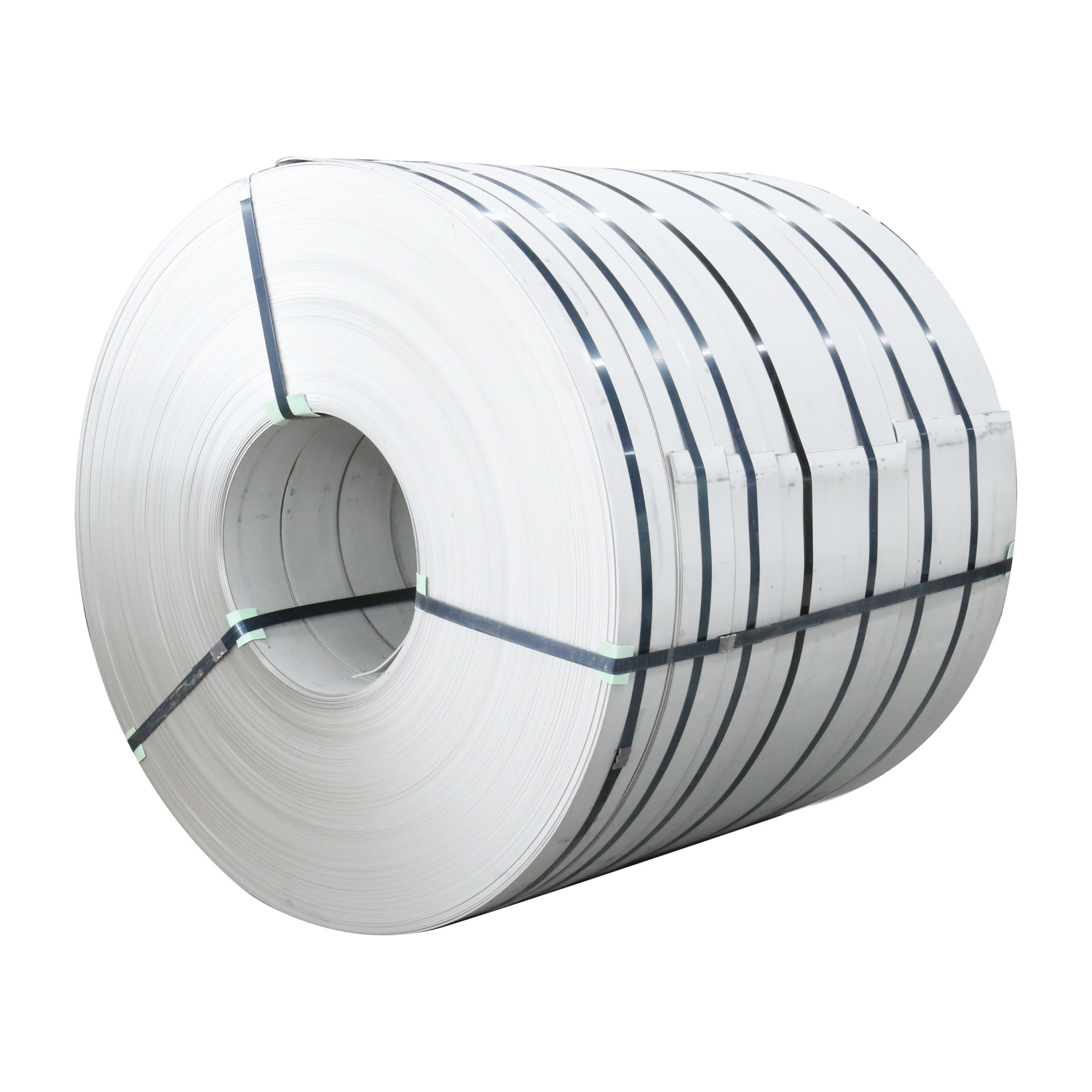

المزايا الأساسية لموردي لفائف سبائك النيكل

يقدم موردو لفائف سبائك النيكل العديد من المزايا الأساسية التي تجعلهم شركاء مفضلين للشركات:

-

مواد عالية الجودة: يوفر الموردون لفائف سبائك النيكل المصنوعة من مواد عالية الجودة معروفة بقوتها الفائقة ومقاومتها للتآكل وخصائص مقاومة الحرارة.

-

الخبرة الفنية: يمتلك الموردون معرفة وخبرة متخصصة في تصنيع وتوزيع لفائف سبائك النيكل ، مما يضمن تسليم المنتجات التي تلبي معايير الجودة الصارمة.

-

خيارات التخصيص: غالبا ما يقدم الموردون خدمات التخصيص ، مما يسمح للعملاء بتخصيص ملفات سبائك النيكل وفقا لمتطلباتهم المحددة ، مثل الحجم والسمك والتكوين.

-

التسليم في الوقت المناسب: يعطي الموردون الأولوية للتسليم في الوقت المناسب ، مما يضمن حصول العملاء على طلباتهم على الفور للحفاظ على جداول الإنتاج والوفاء بالمواعيد النهائية للمشروع.

-

الفعالية من حيث التكلفة: يقدم الموردون أسعارا تنافسية وحلولا فعالة من حيث التكلفة ، مما يمكن الشركات من الوصول إلى ملفات سبائك النيكل عالية الجودة دون تجاوز قيود الميزانية.

-

دعم العملاء: يقدم الموردون دعما ممتازا للعملاء ، ويقدمون المساعدة في اختيار المنتج ، والاستفسارات الفنية ، وخدمة ما بعد البيع لضمان تجربة سلسة ومرضية للعملاء.