تطبيقات سبائك النيكل: مادة متعددة الاستخدامات

مقدمة:

سبائك النيكل هي فئة من المواد المعروفة بخصائصها الاستثنائية وتعدد استخداماتها. تتكون هذه السبائك بشكل أساسي من النيكل ، وتظهر مقاومة ممتازة للتآكل ، وقوة عالية ، ومقاومة فائقة للحرارة. تهدف هذه المقالة إلى استكشاف التطبيقات المتنوعة لسبائك النيكل في مختلف الصناعات.

-

صناعة الطيران:

تلعب سبائك النيكل دورا حيويا في صناعة الطيران نظرا لخصائصها الميكانيكية المتميزة ومقاومتها لدرجات الحرارة المرتفعة. يتم استخدامها في محركات الطائرات ومكونات التوربينات الغازية وغرف الاحتراق ، حيث يمكنها تحمل الظروف القاسية والحفاظ على قوتها وسلامتها. -

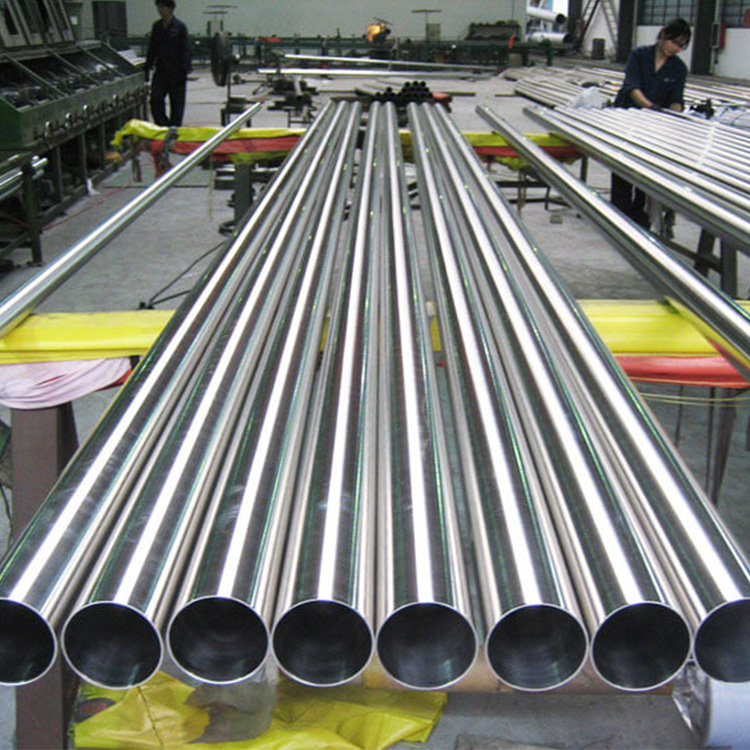

المعالجة الكيميائية:

تعتمد صناعة المعالجة الكيميائية بشكل كبير على سبائك النيكل لمقاومتها للبيئات المسببة للتآكل والمواد الكيميائية المختلفة. تستخدم هذه السبائك بشكل شائع في المفاعلات الكيميائية والأنابيب والصمامات والمضخات ، مما يضمن التعامل الآمن والفعال مع المواد المسببة للتآكل. -

توليد الطاقة:

في محطات توليد الطاقة ، يتم استخدام سبائك النيكل في المكونات الهامة مثل مولدات البخار والمبادلات الحرارية وشفرات التوربينات. تمكنها المقاومة الاستثنائية للحرارة ومقاومة التآكل لسبائك النيكل من تحمل الظروف الصعبة لتوليد الطاقة ، بما في ذلك درجات الحرارة المرتفعة والبيئات المسببة للتآكل. -

صناعة النفط والغاز:

تتطلب صناعة النفط والغاز مواد يمكنها تحمل البيئات العدوانية ، بما في ذلك ظروف الضغط العالي ودرجات الحرارة العالية. تجد سبائك النيكل تطبيقا واسعا في معدات التنقيب عن النفط والغاز وإنتاجه ، مثل الصمامات والأنابيب وأدوات قاع البئر ، مما يوفر مقاومة ممتازة للتآكل والإجهاد الميكانيكي. -

المجال الطبي:

تستخدم سبائك النيكل أيضا في المجال الطبي ، لا سيما في تصنيع الأجهزة الطبية والغرسات. هذه السبائك متوافقة حيويا ، مما يجعلها مناسبة لتطبيقات مثل زراعة العظام وأدوات طب الأسنان والأدوات الجراحية. تضمن مقاومة التآكل وقوة سبائك النيكل طول عمر وموثوقية الأجهزة الطبية. -

صناعة البتروكيماويات:

تجد سبائك النيكل استخداما واسعا في صناعة البتروكيماويات بسبب مقاومتها للمواد الكيميائية العدوانية ودرجات الحرارة المرتفعة. يتم توظيفهم في معدات مثل المبادلات الحرارية والمفاعلات وأنظمة الأنابيب ، مما يضمن التعامل الآمن مع المواد المسببة للتآكل في مصانع البتروكيماويات. -

الإلكترونيات والهندسة الكهربائية:

تستخدم سبائك النيكل في تطبيقات الإلكترونيات والهندسة الكهربائية نظرا لموصليتها الكهربائية العالية ومقاومتها للأكسدة. يتم استخدامها في الموصلات الكهربائية وقواطع الدائرة وعناصر التسخين وأسلاك المقاومة ، مما يوفر أداء موثوقا به وطول العمر في هذه التطبيقات.

استنتاج:

سبائك النيكل هي مواد متعددة الاستخدامات مع مجموعة واسعة من التطبيقات في مختلف الصناعات. مقاومتها الاستثنائية للتآكل ، وقوتها العالية ، ومقاومتها الفائقة للحرارة تجعلها لا غنى عنها في صناعات الفضاء والمعالجة الكيميائية وتوليد الطاقة والنفط والغاز والطبية والبتروكيماويات والإلكترونيات. تساهم الخصائص الفريدة لسبائك النيكل في كفاءة وسلامة ومتانة المكونات والمعدات الهامة في هذه القطاعات ، مما يعزز مكانتها كخيار مادي قيم للتطبيقات الصعبة.